“In the past, the Industry spent millions to create NASA like monitoring rooms with SCADA that provided limited capability. Today, one device provides more to monitor and control anything from anywhere at a price stripper wells can afford.”

The Smart Pumper TM platform supports various forms of Artificial lift. However, one should begin using a Smart Pumper on the first day you complete a well even if it is “a flowing well” to data log, monitor and control the operational aspects of the flowing well site. You can open and close proportional valves to help regulate the flowing rate, close-in the well on a high tank level fault and other fault conditions that can be set-up. Plus, control chemical pumps and more at the same time. After the flowing well declines and a form of artificial lift is required (plunger lift, gas lift, or systems with a pump), continue using the same Smart Pumper to perform the next task through the full life cycle of a well.

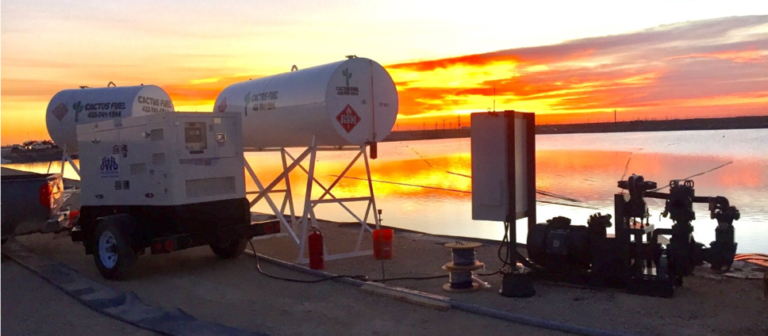

The patented precision pump control aspect of the Smart Pumper will handle pumping wells for you perfectly as well as manage your salt water disposal system too.

The Smart PumperTM platform can perform all of the tasks described below and most of the tasks from a single unit. Obviously, each offtake well would require one Smart Pumper each; however, at each site you will find that you can perform multiple tasks.

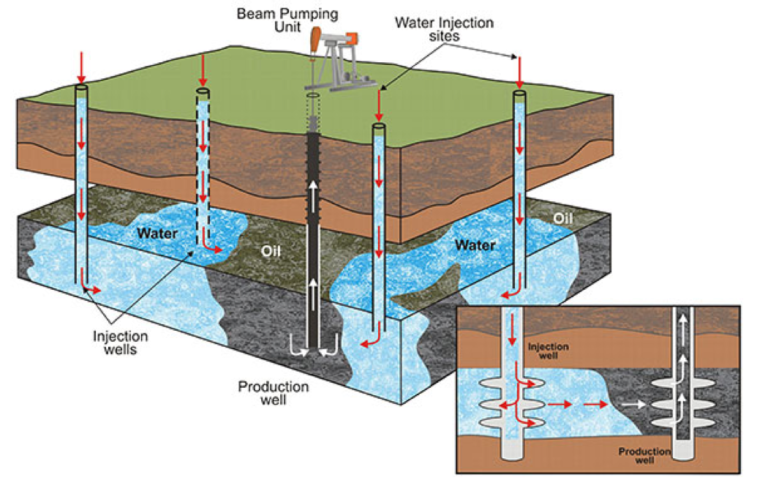

Automate Your Offtake Wells to respond to fluid levels in real time and learn what well responds first to verify or correct geological assumptions, monitor and control the artificial lift device, monitor the flowlines back to your central battery and meter oil, gas and water rates.

Automate the Injection Pump Site and these pumps will match the water-supply-inflow and achieve and maintain a specific tank level above suction for the smoothest operation. Plus, automate Chemical Injection and operate the chemical pumps in perfect harmony with the primary water injection pumps to avoid over and/or under dosing. Plus, control and regulate Proportional Valves in your manifold to distribute water more effectively. Plus, set HSE fault conditions covering Injection Pressures, Flow Line Pressures, Well Bore Fluid Levels, Tank Levels, Meter rates and more.

The Smart Pumper ™ remotely controls and monitors chemical injection pumps at the same time that it controls and monitors artificial lift systems. The method used to automate chemical pumps is tied to Smart Pumper’s patented precision pump speed control based upon real time fluid level to the specific level you wish to achieve and maintain over time. In other words, as Smart Pumper automatically changes the speed of an artificial lift device or surface pumps, it will automatically change the speed of a series of chemical pumps to keep chemistry perfectly aligned with automated output.

You can change your mode of operation from the described automated form above to manual control as well so that you can manually change the chemical injection rate(s) independent of the artificial lift operation. Set conditions, warnings, faults, and change other operational aspect of your facility remotely as well. Never waste a gallon again. Just in time inventory requests. Inventory delivery verification and accountability covering Current Rate, Current 24 Hours, Last 24 Hours, Current Month, Last Month and Cum Total from start.

Mining operations have a few challenges that can be overlooked such as the water levels in their reservoirs and if too high, the earthen dam can give-way. The Smart Pumper TM is a quick and cost-effective solution to “put eyes” on a situation within a few days of your request for services regardless of the location.

In the case of reservoir management, as levels rise, the Smart Pumper TM will provide alerts to the designated teams and activate a series of high volume transfer pumps (if the need arises) to move large volumes of water to other storage sites to help protect these levies.

Water quality data logging and pit aeration are a couple more features provided by the Smart Pumper TM that the Mining Industry can benefit from and our integration team can help you deploy.